- Home

- Hard Facing

HARDFACING

HARDFACING

Hardfacing is a metalworking process where harder or tougher material is applied to a base metal. It is Hardfacing WELDED to the base material, and generally takes the form of specialized electrodes for ARC WELDING or filler rod for OXYACETYLENE and TIG welding. Powder metal alloys are used in (PTA) also called Powder plasma welding system and THERMAL SPRAY processes like HVOF, Plasma spray, Spray and Fuse, etc.

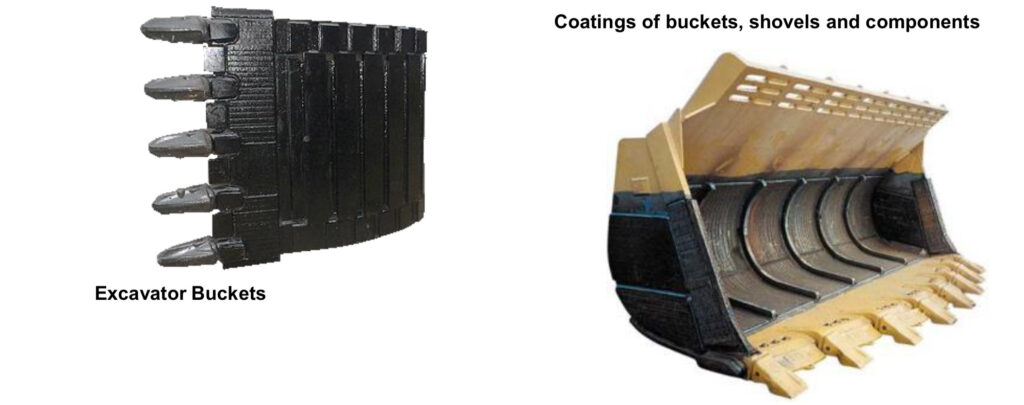

Hardfacing may be applied to a new part during production to increase its WEAR RESISTANCE, or it may be used to restore a worn-down surface. Hardfacing by arc welding is a surfacing operation to extend the service life of industrial components, pre-emptively on new components, or as part of a maintenance program.[1] The result of significant savings in machine down time and production costs has meant that this process has been adopted across many industries such as STEEL, Cement, MINING, PETROCHEMICAL, Power, Sugar cane and Food. According to the results of an experimental study, the SMAW (SHIELDED METAL ARC WELDING) and the GMAW (GAS METAL ARC WELDING) hardfacing processes were effective in reducing the wear on the mouldboard ploughshare. With the SMAW and GMAW hardfacing processes, the life span of the ploughshare was increased approximately 2 times [1].[2]

Extensive work in research has resulted in the development of a wide range of alloys and WELDING PROCEDURES. The optimum alloy selection is made considering the component service conditions and feedback of the service performance.

For each industrial application and wear phenomena, there is a welding electrode to provide wear resistance.

Hardfacing can be deposited by various welding methods

- Shielded Metal Arc Welding (SMAW)

- Gas Metal Arc Welding (GMAW), including both gas-shielded and open arc welding

- Oxyfuel Welding (OFW)

- Submerged Arc Welding (SAW)

- Electroslag Welding (ESW)

- Plasma Transferred Arc Welding (PTAW), also called Powder Plasma welding system

- Thermal spraying

- Cold polymer compounds

- LASER CLADDING

Commonly applied materials include cobalt-based alloys (such as STELLITE), nickel-based alloys, CHROMIUM CARBIDE alloys and NOREM.

Hardfacing is sometimes followed by hot stamping to refinish the part

or add color or instructional information to the part. Foils or films

can be used for a metallic look or other protection.[3]

For more information on hardfacing products, please review these PDF

- MINING KSTS PRESENTATION ENGLISH

- KESTRA USA 11

- KESTRA FLUX CORED WIRE CATALOG-MSC

- KESTRA ELECTRODE CATALOG ENGLISH-MSC

- CEMENT KESTRA PRESENTATION MSC