- Home

- HIGH PURITY ZnAl ALLOY WIRES

ZINC ALUMINUM WIRE

PRODUCT

SPECIFICATION

- TITLE: THE 85/15 (Zn/Al)

- SUPER DELUXE

- QUALITY SPRAY WIRE

- PS:31

- ISSUE NO: 01

- REV. NO.:02

- DATE: 01.01.2015

REQUEST INFORMATION

SCOPE | GENERAL | CHEMICAL COMPOSITION: |

This Specification covers manufacturing of 85/15 (Zn/Al) Spray wire used for arc and flame spraying and are well-known for its excellent quality. The 85/15 Zn/Al wires are produced to meet requirements as accordance to ISO 14919 | The 85/15 Zn/Al wires are manufactured from virgin S.H.G Zinc and Aluminum Ingots by the process which ensures that the material meets requirement of the sprecification. The manufactured wire should have a smooth finish, free from defects that may affect the feeding of the wire to the spray gun. | The material consists of: 1. 85% ± 1% (weight) Electroplated Zinc With Purity of 99.99% |

Maximum impurities (%) | Maximum impurities (%) | Maximum impurities (%) | Maximum impurities (%) | Maximum impurities (%) | Maximum impurities (%) | Maximum impurities (%) | ||

Standard Specification | Si | Pb | Fe | Cd | Sn | Cu | Zn | |

99.99 | ISO 752 | – | 0.003 | 0.003 | 0.003 | 0.001 | 0.002 | – |

99.7 | ISO 115 | 0.1 | – | 0.0 | – | – | 0.1 |

PROPERTIES

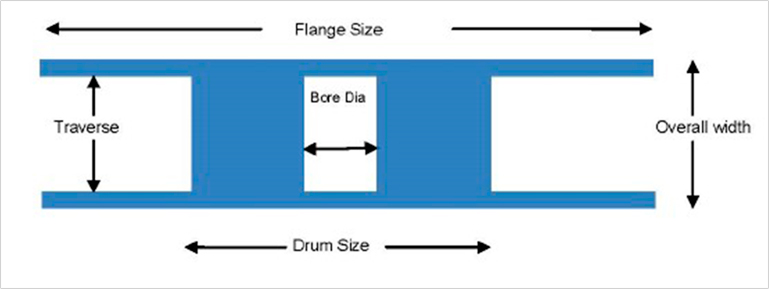

No | Type | Flange Size | Bore Dia. | Drum Size | Traverse | Overall Width | Capacity in Lbs. |

1 | KE 340 | 13.385″ | 2 1/21″ | 5.354″ | 4.763″ | 5 2/17 | 77 Lbs. |

2 | KE 300 | 11.811″ | 2.027″ | 8.346″ | 3.346″ | 3.858″ | 33.06 Lbs. |

3 | KE 270 | 10.629″ | 2.047″ | 5.826″ | 3.539″ | 4.055″ | 44.09 Lbs. |

HAZARDOUS SUBSTANCE CONTROL

Substance | Concentration Limits | Substance | Concentration Limits |

Lead (Pb) | < 1000ppm | Bromine (Br) | < 900ppm |

Mercury (Hg) | < 1000ppm | Chloride (Cl) | < 900ppm |

Cadmium (Cd)³! | < 1000ppm | sum of Bromide and Chlorine | <=1500 ppm max |

Hexavalent Chromium | < 1000ppm | Antimony | < 900ppm |

Polybrominated Biphenyl (PBB) | < 1000ppm | Red Phosphorous | < 100ppm |

Polybrominated Disphenyl Ether (PBB) | < 1000ppm |

REFERENCE STANDARD | PACKING | HANDLING AND STORAGE |

IS-12447, DIN 14919:2001, EN 1179 Z1, ASTM B833-06 | The 85/15 Zn/Al wire are packed and supplied in 1. 55 – 66 Lbs. coil | The 85/15 An/Al wires to be stored in cool and dry place and should be kelpt away from direct water contact or heavy moisture area. |

TOLERANCE ON DIMENZIONS

Nominal Diameter | Tolerance |

Ø ≤ 0.1181 | -0.0019 |

≤ 0.1181 Ø ≤ 0.1574 | -0.0019 |

SHELF LIFE | TOLERANCE ON DIMENZIONS |

The 85/15 Zn/Al wire has infinite shelf life. We recommend best for use within one year of manufacturing to get best results in application. | The 85/15 Zn/Al wire has infinite shelf life. We recommend best for use within one year of manufacturing to get best results in application. |

No | Type | Flange Size | Bore Dia. | Drum Size | Traverse | Overall Width | Capacity in Lbs. |

1 | KE 340 | 13.385″ | 2 1/21″ | 5.354″ | 4.763″ | 5 2/17 | 77 Lbs. |

2 | KE 300 | 11.811″ | 2.027″ | 8.346″ | 3.346″ | 3.858″ | 33.06 Lbs. |

3 | KE 270 | 10.629″ | 2.047″ | 5.826″ | 3.539″ | 4.055″ | 44.09 Lbs. |