- Home

- SPRAY FUSE GUN

SPRAY FUSE GUN

All Products

Thermal Spray Wire & Welding Wires

Process

Material

THICKNESS

APPLICATION

BENEFITS

Spray & Fuse coating materials are generally Nickel or Cobalt base alloys that use boron, phosphorus or silicon based compositions & can be sprayed on metallic surfaces which experience high levels and long durations of wear combined with high stresses. The powder is sucked in by the oxy-acetylen fluid, ejected onto the workpiece and melted by atomic diffusion.These wear resistance coatings provide the following benefits:-

Spray & Fuse coating exceptionally produces metallurgical bond with the substrate unlike the other

thermal spray processes which form mechanical bonds.

1 – 6 welding heads for the same blowpipe.

Two supplementary heating heads to apply powder to surfaces.

Performance of the equipment: 0.5 – 5 Kg powder per hour.

Robust hopper with a content of 70g, resistant against heat emission, easy to fill and empty because of

the cover tightened with or-ring sealing.

Inspite of taking more physical abuse this coating maintains its bond to the substrate with resistance

against chipping in comparison to other coating processes.

Higher hardness is maintained with rise in temperature of the substrate.

These coatings will not anneal as they will regain their original hardness when the substrate temperature

returns to ambient.

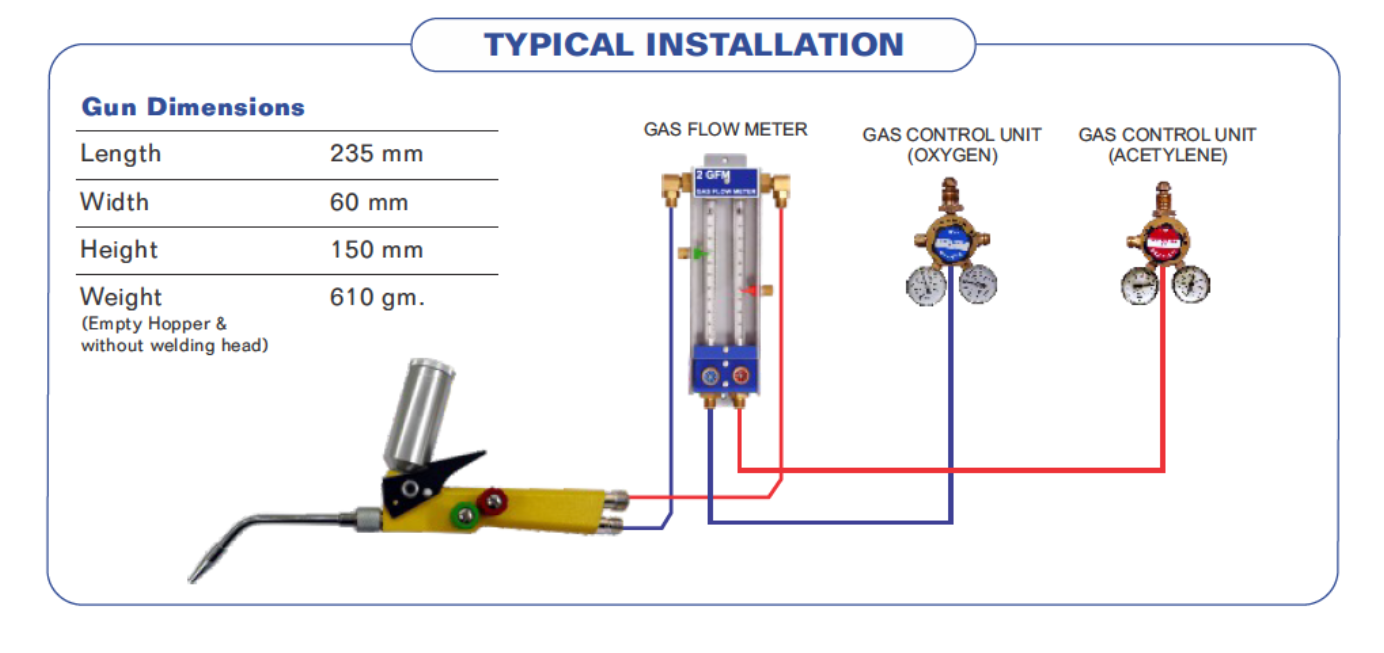

Gas inlet: ¼” right hand thread for oxygen and ⅜” left hand thread for acetylen

- The parameters given are only for reference purpose. Actual values may differ depending upon the geometry and size of the job.

- Buyer to specify wire diameter, material and fuel gas to be used while ordering the gun.

[email protected]