- Home

- POWDER FLAME SPRAY GUN 6PM-II

POWDER FLAME SPRAY GUN 6PM-II

All Products

Thermal Spray Wire & Welding Wires

The Metal Coat 6PM-II powder flame spray system is ideal for demanding, high-volume production performance and consistent coating results. It is suitable for coating hard facing alloys, ceramics, metals and carbide powders. The 6PM-II powder flame spray gun is the perfect choice to apply high-quality coatings to solve many surface problems such as machine element repairs, dimensional restoration, corrosion protection, abradable and wear-resistance coatings. The 6PM-II powder flame spray gun has high spray rates and low gas consumption. The coatings made using 6PM-II system results in higher deposit efficiencies. These guns are convenient to use, easy to learn, operate and maintain them.

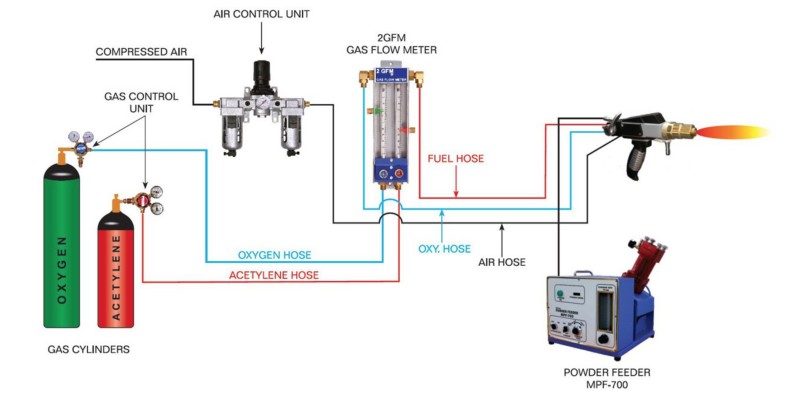

This model is suitable for all-purpose use. Hence, it can be used to spray an extensive range of coating materials like self-fluxing alloys, ceramics, selfbonding materials, and conventional thermal spray powders like steels, stainless steel, bronze, and aluminium and nickel alloys. The 6PM-II Powder Flame Spray System needs an external powder feeder unit, which maintains a consistent and accurate supply of powder to the gun. For more information on the powder feeders, please have a look at our powder feeder section.

STANDARD ACCESSORIES

AIR JET ASSEMBLY

EXTENSION NOZZLE

SPECIFICATIONS

SIZE-

WEIGHT-

| Gases | Consumption |

| Acetylene | 20 to 34 NLPM |

| Hydrogen | 108 to 170 NLPM |

| Oxygen | 20 to 45 NLPM |

| Compressed air | 0.85 m3/min at 4.5 bar |

POWDER FLAME SPRAY GUN 6PM-II INSTALLATION

TYPICAL SPRAYING RATE OF 6PM-II GUN

| Powder | Spray Rate(Kg/Hr) | Deposit Efficiency |

| Ceramics | 0.9 Kg/hr | 25 – 75% |

| Metallic | 2.7 Kg/hr | 80 – 90% |

| Self Fluxing | 9.1 Kg/hr | 85 – 95% |

- The parameters given are only for reference purpose. Actual values may differ depending upon the geometry and size of the job.

- Buyer to specify wire diameter, material and fuel gas to be used while ordering the gun.

[email protected]